Electronic devices or components have become an integral part of our lives today. Our life seems incomplete without television, mobile phone, computer, and similar such gadgets. Also, electronics has forayed much into the other sectors such as medical, defense, finance, automobile, and others. As we know, electronic devices cannot be made without PCBs, and hence the demand for the latter has gone up as well. So what is a PCB assembly? A PCB assembly or PCBA comprises PCBs, required components or parts, and electrical and electronic accessories such as wires. Additionally, small-sized PCB Assemblies have been integral to the shrinking size and niche features of electronic devices. This post discusses more about the types of PCB assemblies, their application areas, the process of soldering and assembling.

Types of PCB Assemblies

Here are various

types of PCB assemblies based on the PCB design:

-

Single-Sided Surface mounted device (SMD): In this type, surface mounted devices are assembled on the single side of the PCB.

-

Double-Sided SMD: In this type, SMDs are mounted on both sides of PCBs.

-

Single-Sided Mixed Assembly: In this type, SMDs and through-hole clouds (THCs) are mounted on one side of the PCB.

-

Mixed Assembly on One Side and Simple SMD on the Other: In this type, SMDs and THCs are assembled on one side while only SMDs are mounted on the other side.

-

Plug-in on One Side and Simple SMD on the Other: In this type, THCs are mounted on one side while only SMDs on the other side.

Steps Involved in the PCB Assembly Process

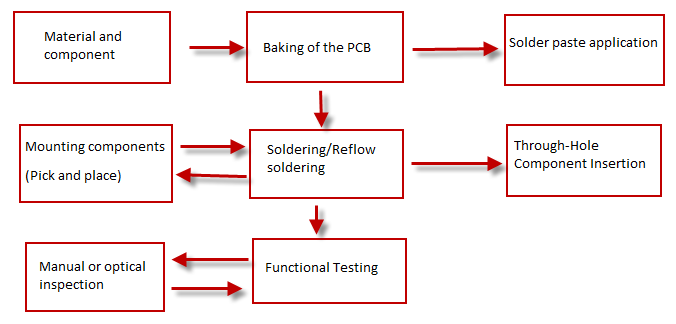

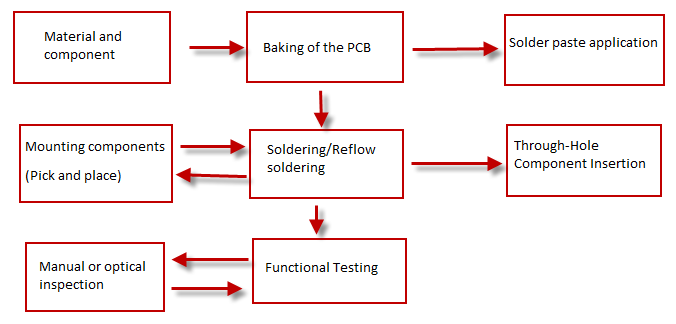

There are a number of steps carried out in the PCB Assembly process, although they may vary depending upon the project requirements. Nowadays, surface mounted components are almost always used. We have listed the steps below considering surface mount components on the board:

-

Solder Paste: Application of solder paste is essential whenever soldering needs to be done on the board. It is a paste of solder grains and flux, which is applied on the board with the help of a solder screen. It is inserted into the holes with the help of a runner and deposited on the solder pads. It is crucial to use the exact amount of solder paste. In case of wave soldering, which is commonly used these days, this initial application of solder paste is not required. This is because the wave soldering machine does this task.

-

Pick and Place: This is primarily about picking the components and placing them correctly on the board. In this process, a programmed machine loaded with the required component reels, picks up the parts and mounts them in the right position on the solder pasted board. The solder paste helps the components remain in their place. If more glue is required, the pick and place machines can do that job. However, the presence of glue makes repairs in the future difficult. The PCB design information document helps with the correct programming of the machine to mount the components in the right place.

-

Reflow Soldering: This is an important step in the entire PCB assembly process. Soldering is a process where these components are passed through a soldering machine, so that they remain fixed on the board. Wave soldering may be used for some processes. However, reflow soldering is now widely used for most PCB assemblies. In reflow soldering, a reflow oven, which comprises a number of heaters is used so that the solder paste eventually dries and solidifies, thus fixing the components on the board. The board is passed through the heaters at a temperature of almost 250 degrees Celsius. This heat causes the solder paste to melt. After this, the board passes through a series of cooler heaters, which helps the solder paste to solidify, and thus forms permanent solder joints to fix in the surface mount components (SMDs).

-

Through-Hole Component Insertion: Apart from SMDs, a variety of components such as through-hole components are present on a PCB. Through-holes are plated across the PCB and used by other components to pass signals from one side to the other. In this case, a normal solder paste does not serve the purpose. Therefore, either manual soldering or wave soldering technique is used. In manual soldering, one person adds just one component and then the board passes on to the next person. The wave soldering process is automated, wherein a wave of molten solder washes on the bottom side of the board, on a conveyor belt. This technique, however, cannot be used for double-sided PCBs.

-

Manual Inspection and Quality Control: Manual inspection although done to some extent is suitable only for simple PCBs. However, nowadays, PCBs are quite complex and there are many components involved. To inspect all these components, optical inspection machines are used. They can identify poorly soldered joints or if components are mounted in the wrong place. So, immediate rectification may be possible.

-

Functional Testing: This actually comprises a dry run or simulation of sorts to check all the functionalities of the PCB. This includes checking for current and voltage fluctuations, peaks beyond the predetermined range, other electrical attributes, and more. If the PCB fails, it can be either recycled or scrapped depending upon the type of failure. This sort of inspection is important at each level of PCB formation to avoid any flaws in other PCBs produced later.

Here is a very concise flowchart which depicts the entire PCB assembly process in case of surface mount components:

PCBs are there wherever electronic components are used or fitted into various devices. So, by now they have almost become ubiquitous. They are used across industries such as electronics & telecommunication, transportation systems, medical & healthcare, defense, aerospace, weather detection systems, security systems, cameras, automation in the manufacturing sector, and so on.

It is essential that your

PCB assembly is accurate and functioning well. So, it is essential that you deal with a reliable manufacturer and service provider of PCB assemblies. Sierra Assembly is a proud US-based manufacturer and service provider of PCB assemblies. The company has been providing PCB assemblies to its clients across industries such as electronics and telecommunication, transportation systems, medical and healthcare, and so on.