Subscribe to get the latest news and updates. No span, we promise.

The ground plane is an essential component in the design of printed circuit boards (PCBs). It works as the solid foundation which supports the functionality of electronic circuits. The ground plane in the circuit board is critical in optimizing circuit performance because it ensures signal integrity and minimizes electromagnetic interference. So, let's delve in and discover more about the PCB ground plane, looking at how it turns circuit boards from ordinary components to efficient electronic systems.

In this article, we'll go over the fundamentals of the ground plane, its significance in circuit board design, and the key rules that govern its use.

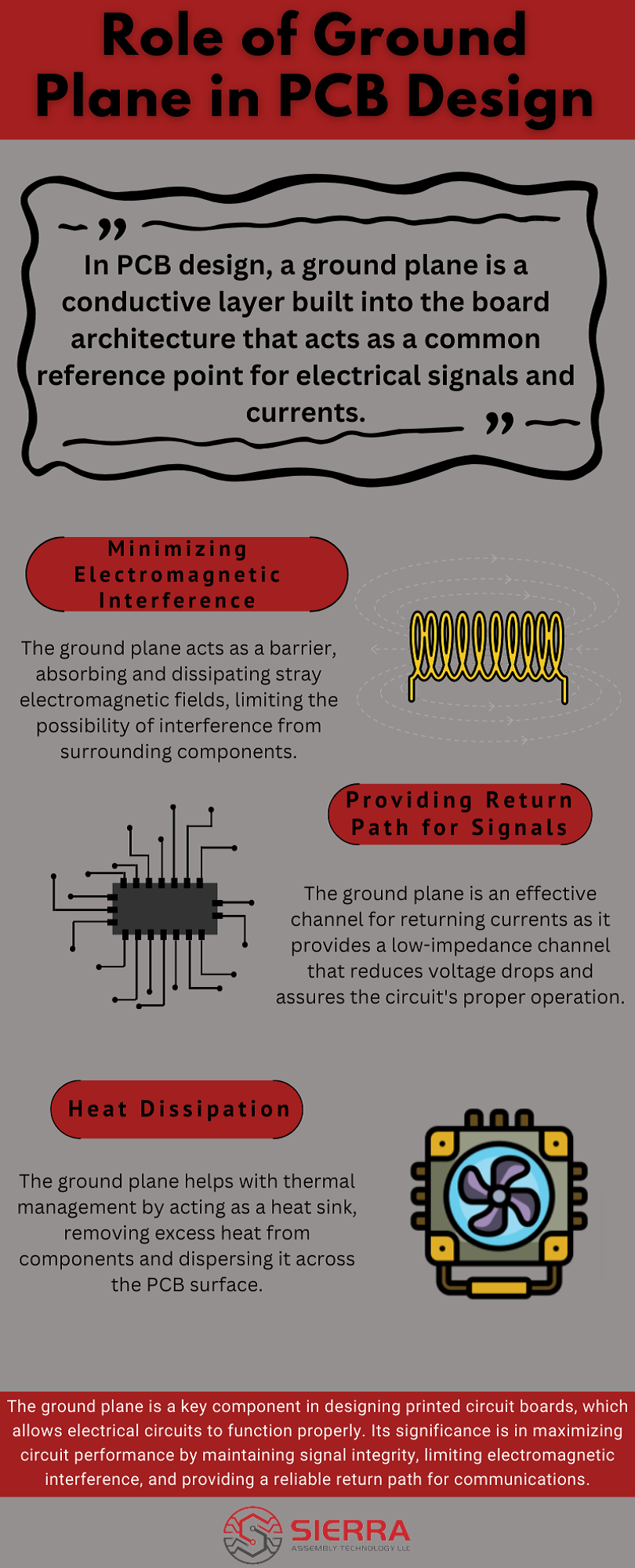

In PCB design, a ground plane is a conductive layer built into the board architecture that acts as a common reference point for electrical signals and currents. Its primary function is to provide a low-impedance channel for returning currents while maintaining a steady ground potential throughout the circuit.

This ensures signal integrity by reducing noise and interference, which improves the overall performance and reliability of the electrical system. Also, ground planes help with thermal management by dispersing heat created by components, which increases the longevity of the PCB and its components. Overall, PCB ground planes are crucial to improving the functionality and efficiency of PCB designs.

The ground plane is a vital part of PCB design since it acts as the foundation for electronic circuits. Its significance comes from its capacity to ensure signal integrity, reduce electromagnetic interference, offer a reliable return path for communications, and help in heat dissipation, especially in high-power applications.

Through these roles, the ground plane optimizes the performance and reliability of printed circuit boards, making it an essential component in modern electronics.

Another important purpose of the ground plane in PCB design is the reduction of electromagnetic interference (EMI). The ground plane acts as a barrier, absorbing and dissipating stray electromagnetic fields, limiting the possibility of interference from surrounding components or external sources.

This shielding effect reduces crosstalk between signal traces, reduces noise, and improves the PCB's electromagnetic compatibility (EMC). The ground plane improves the dependability and stability of electronic systems by decreasing EMI, especially in settings with strong electromagnetic activity.

Current flows in loops in electrical circuits, therefore signals must have a return channel to complete the circuit. The ground plane is an effective channel for returning currents as it provides a low-impedance channel that reduces voltage drops and assures the circuit's proper operation. The ground plane contributes to signal integrity by providing a dependable return path, preventing difficulties like ground bounce. This allows electronic devices to run smoothly.

In high-power applications, electronic components create huge amounts of heat during operation, which can have a negative impact on performance and reliability if not managed effectively. The ground plane helps with thermal management by acting as a heat sink, removing excess heat from components and dispersing it across the PCB surface. This helps to avoid isolated hotspots, lowers the chance of component failure due to overheating, and extends the life of electrical systems.

The ground plane is critical to the thermal stability and endurance of PCBs in high-power applications because it allows for good heat dissipation.

Exploring Types of PCB Ground Planes: Single, Double, and Multi-Layer Options

When designing printed circuit boards (PCBs), the choice of ground plane configuration is critical to the overall efficiency and reliability of electronic devices. Let's look at the different types of PCB ground planes—single-layer, two-layer, and multi-layer—and discuss their unique properties and functionality.

In single-layer PCBs, the ground plane is incorporated on one side of the board and usually serves as the bottom layer. While single-layer PCBs are simpler and less expensive, their lack of a separate ground plane layer might compromise signal integrity and electromagnetic interference (EMI) management.

Two-layer PCBs have a separate ground plane layer placed between two signal layers. This arrangement provides better signal integrity and EMI management than single-layer PCBs. Two-layer PCBs reduce signal distortion and interference by providing a distinct ground plane layer. This improves the overall performance and reliability of electronic circuits.

Multi-layer PCB includes three or more layers, including signal and ground plane layers stacked together. In comparison to single or two-layer PCBs, this arrangement provides improved signal integrity, EMI management, and routing flexibility. Multi-layer PCBs are commonly used in complicated electronic systems with high routing density and demanding performance requirements.

Each form of PCB ground plane—single-layer, two-layer, and multi-layer—provides unique advantages and trade-offs, catering to different design needs and constraints. Understanding the qualities and capabilities of each type is critical for determining the best solution for a specific application.

When building PCB ground planes, accurate placement is important for maximizing circuit performance. Ground planes should be placed strategically to reduce signal distortion and electromagnetic interference (EMI). Placing the ground plane close to signal traces and components decreases loop area, reduces inductance, and improves signal integrity.

Additionally, putting ground planes near high-speed or high-power components helps in heat dissipation, improving thermal management inside the PCB.

To avoid signal degradation and interference, traces must be routed properly around the ground plane. Signal traces should be routed on the same layer as their ground plane to reduce impedance discontinuities and signal reflection.

Signal traces and ground planes must be properly separated to avoid crosstalk and guarantee signal integrity. Using controlled impedance routing strategies and avoiding sharp bends in traces can help improve signal performance in PCB designs.

Proper ground plane connection is crucial for maintaining a continuous and low-impedance ground reference across the PCB. To reduce ground loops and impedance fluctuations, ground planes should be linked with many vias dispersed over the board. Stitching vias are often used to create a strong connection between multiple levels of the ground plane, which reduces the possibility of ground bounce and signal noise.

Compliance to clearance and spacing standards is critical to preventing unintentional electrical connection and ensuring the PCB's reliable operation. To avoid short circuits and signal interference, there should be sufficient distance between traces and ground planes.

Proper spacing between vias and components prevents solder bridging and provides adequate insulation between conducting elements. Designers can reduce the risk of electrical failure and increase PCB reliability by following to industry-standard clearance and spacing rules.

Dual-sided ground planes have numerous benefits, including improved signal integrity, thermal control, and routing flexibility. Let's look at these benefits thoroughly to see how dual-sided ground planes improve the functionality and efficiency of printed circuit boards.

Finally, the ground plane is a key component in the design of printed circuit boards (PCBs), which allows electrical circuits to function properly. Its significance is in maximizing circuit performance by maintaining signal integrity, limiting electromagnetic interference, providing a reliable return path for communications, and helping in heat dissipation, particularly in high-power systems.

Understanding the basics, relevance, and implementation standards of the printed circuit board ground plane helps designers to improve the efficiency and dependability of modern electronic systems.