Subscribe to get the latest news and updates. No span, we promise.

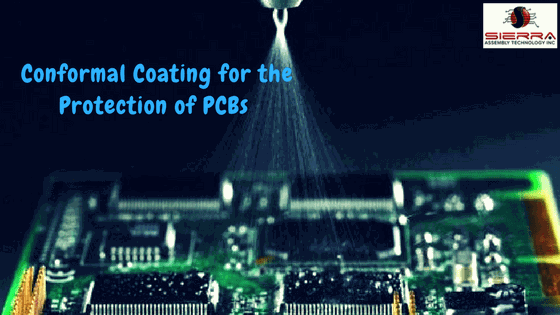

Printed circuit boards (PCBs) often get damaged because of dust, salt spray, contamination, fungus, corrosion caused due to harsh environments, and moisture. Thus, in order to protect PCBs from getting damaged, a protective dielectric layer, called conformal coating is applied over them. This coating is of great help when products are to be used in heat- and moisture-prone conditions. Is it really important to do conformal coating to your product? What are the benefits of these coatings? What is the process of doing conformal coating? Questions like these might be popping up in your mind. Read this post to get answers to all these questions that might be bothering you.

Just to have some basic understanding of this coating, just go through some key characteristics that the coating has.

One of the most basic questions that arises into the minds of many is - why is it important to have a product conformal coated. Here are some benefits, which explain the importance of this type of coating.

Conformal coating can be made from a wide range of materials. Following are the most popular materials used in conformal coatings:

Now, that you have a fair understanding of conformal coating, you would be eager to know how this coating is done. Without beating around the bush, it’s time to come to the point. Conformal coating can be applied in following different ways to protect PCBs from potential damages:

So, this explains the importance, characteristics, and process of applying the conformal coating. Do you want to do this coating to your PCBs as well? Do you wish to know more about the coating? For all these purposes, you can always consult an expert. You can consider contacting Sierra Assembly, which is one of the leaders in PCB assembly manufacturing and coating.